BPP Tech has a 1,000m² laboratory and testing facility located in Newcastle-upon-Tyne. This has room and test equipment to accommodate for a wide range of inspections, testing and forensic investigations of SURF products, pipelines, subsea components and power cables.

Forensic Examination and Dissection

BPP Tech have undertaken numerous forensic dissections of failed or faulty pipelines/SURF equipment as part of a root cause analysis (RCA) investigation. Equipment is taken apart carefully component by component with measurements, photographs and observations taken throughout. This informs a final report in which the as-received condition of the equipment sample is assessed, and the likely failure or fault mechanisms are determined and backed up by research and analysis.

Mechanical Testing

A wide range of mechanical testing is available to establish the mechanical properties of a full cable or individual components. Typical testing includes one or a combination of bending, tension and torsional testing. These tests can be used to also establish cable performance and behaviour under set conditions, such as during installation and operation.

Electrical Testing

Electrical testing of power cables can be a useful tool in determining the nature of or the root cause of a fault or failure. BPP Tech can perform a variety of electrical tests according to IEC standards to determine cable or component performance. These tests can then allow us to determine possible failure modes and issues in cable design and manufacture.

Material Chemical and Mechanical Evaluation

It is important to determine the composition of metallic components as well as their bulk mechanical properties in a forensic investigation or RCA. The chemical make-up of a material can reveal the cause of behaviours which can be substantiated by subsequent material testing. This is performed using various spectroscopy methods to determine elemental composition and laboratory mechanical tests including tensile, hardness and impact testing.

Thermal Testing

A variety of tests including Differential Scanning Calorimetry and Thermo-Gravimetric Analysis can be used to evaluate the thermal properties of non-metallic components and their performance during operation. These tests can reveal vital information relating to predicted lifetimes, in addition to highlighting possible failure modes. Additionally, ageing tests of can be performed to determine the functionality and predict performance of a component across the asset’s lifespan.

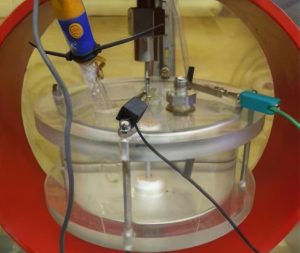

Hydrogen Embrittlement Testing

Hydrogen embrittlement (HE), also known as hydrogen induced cracking (HIC) test, is performed over the armour wires of cables, or SURF asset. The sample is tested under severe conditions, e.g. in simulated seawater containing chloride ion, at maximum negative cathodic potential, and under maximum stress level for a certain time period. After the test, the sample is examined for evidence of cracking, blistering, delamination, etc.

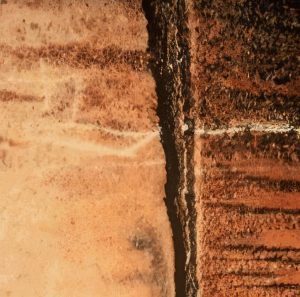

Stress Corrosion Cracking

Sulphide stress cracking (SSC) and stress corrosion cracking (SCC) is performed over the cables and umbilicals or their components such as armour wires. The sample is tested under tension at certain temperature and pressure and in simulated corrosive environments, e.g. containing hydrogen sulphide (H2S), chloride ion, and carbon dioxide (CO2).