BPP Tech operates a dedicated in-house laboratory for equipment and materials testing, staffed by experienced personnel. This capability enables us to offer independent testing and inspection services, verifying component performance and conducting forensic investigations into the root causes of failures for prevention.

Testing Capabilities

- Our laboratory conducts a variety of tests to assess material and component performance.

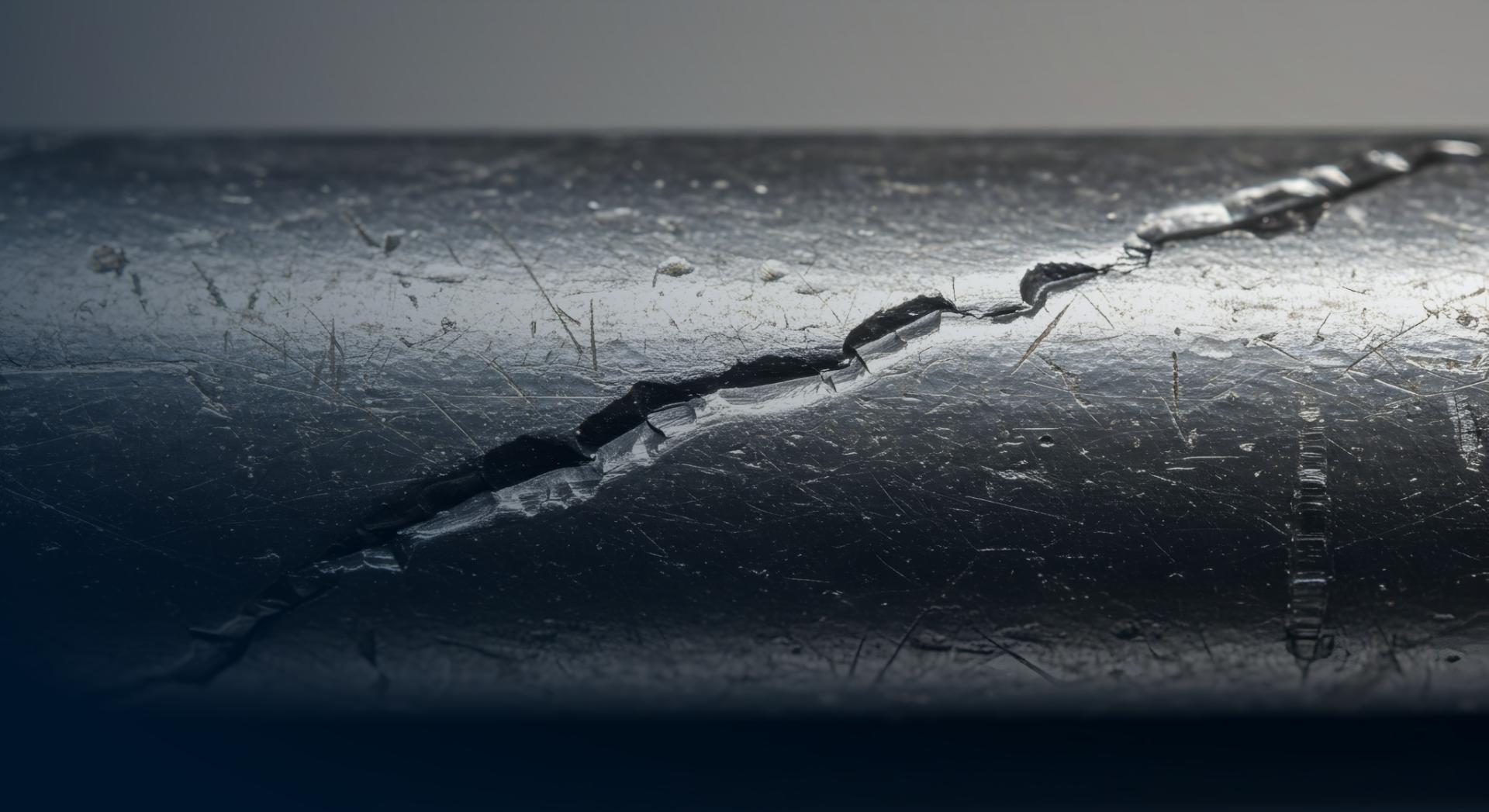

- Types of testing include mechanical strength tests, fatigue life tests, electrical tests, fibre optic performance testing, thermal analysis, environmental stress cracking (ESC), examination, and chemical analyses.

- We apply widely recognised test standards issued by organisations such as the American National Standards Institute (ANSI), American Petroleum Institute (API), American Society for Testing and Materials (ASTM), Insulated Cable Engineers Association (ICEA), International Electrotechnical Commission (IEC), International Organisation for Standardisation (ISO), National Electrical Manufacturers Association (NEMA), and National Association of Corrosion Engineers (NACE).

Testing Objectives

- BPP Tech’s long history of testing work has fulfilled diverse objectives essential for product development, validation, and failure analysis.

- Verification of a structure’s mechanical and fatigue life performance.

- Testing to validate a design method or analysis software outputs.

- Testing as part of a route to product development and product verification.

- Investigation of failure mechanisms and identification of the root cause of failures through whole system and component testing.

Laboratory Equipment

- Our laboratory is well-equipped for comprehensive material analysis and testing. It includes metallurgical sample preparation and inspection tools, materials microscopy, and a variety of specialised test sets for identifying material composition.